How to Measure Tire Size

Selecting the correct tire size is crucial for maximizing your vehicle's performance. Well-fitted tires significantly enhance stability, handling, and overall driving experience, delivering the performance and safety you desire.

Incorrect tire size can negatively affect your car’s ability to brake and increase your risk of accidents.

Tire sizes may seem technical, but understanding how to measure tire size can help you make more informed decisions for your vehicle.

In this article, we will break down the essential aspects of tire sizes and provide a guide to assist you in making accurate measurements for better tire selection.

Understanding Tire Size Terminology

The sidewall of your tires displays a sequence of letters and numbers, each representing important information about the tire's size, type, and even performance characteristics.

By interpreting this information, you can make informed choices and select the appropriate tires that align with your specific needs.

How to Read Tire Size Code

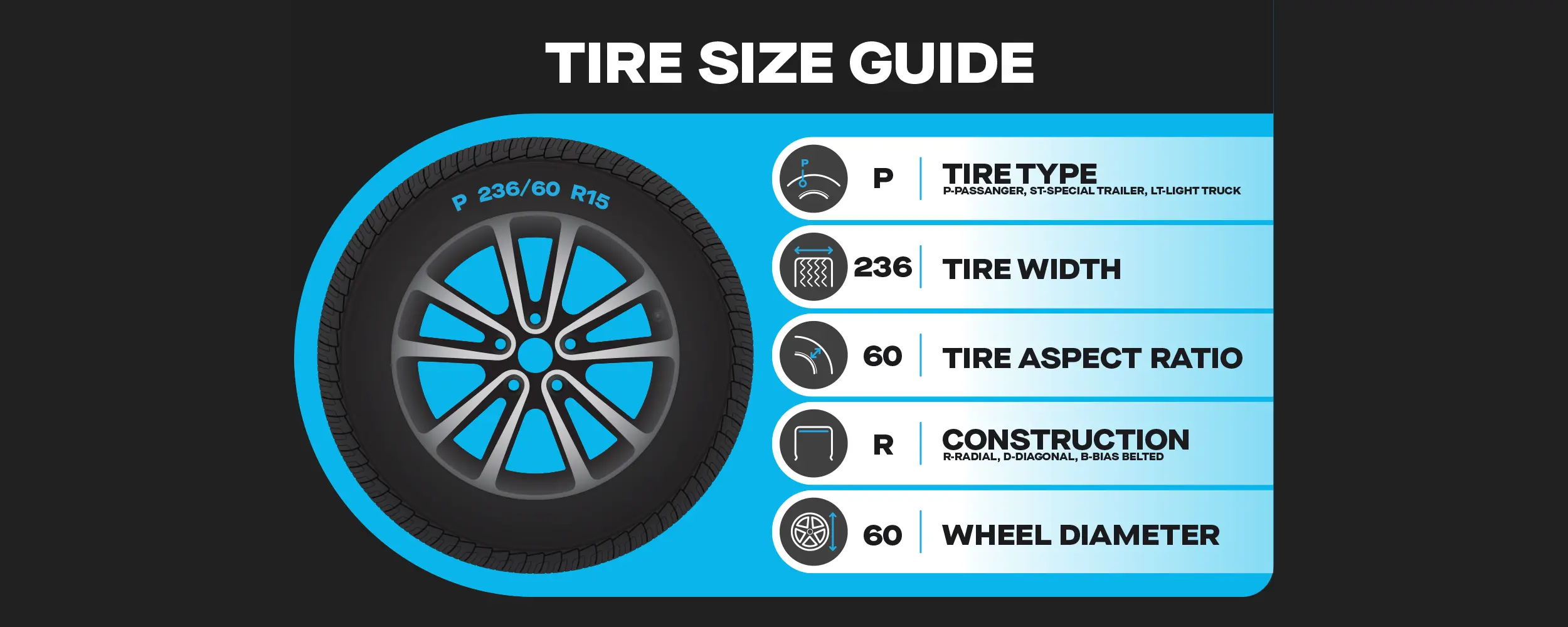

Let's use the tire code P236/60R15 as an example to decode its size. Each letter and number in the code depicts specific tire characteristics.

The first letter denotes the tire type. For instance, P stands for Passenger, ST stands for Special Trailer, and LT stands for Light Truck tire. The next number, 236, indicates the tire width in millimeters, making it 236 millimeters wide.

Then comes the aspect ratio: a measurement of the sidewall height in proportion to the width. In this case, it is 60, which signifies that the sidewall height is 60% of the tire width.

The letter R stands for radial tire, indicating a specific construction type. Nowadays, most car tires are radials. The last number, 15, represents the wheel diameter that can accommodate this tire.

Following the correct measurement format is important to ensure the tire’s compatibility with the vehicle.

Essential Tools for Tire Measurement

The importance of using reliable equipment to measure tires cannot be overstated. To make accurate tire measurements, the following tools are usually required:

- Tape Measure. You can use a measuring tape to measure the tire's overall diameter.

- Tread Depth Gauge. This useful tool measures the depth of a tire’s tread, which can help assess the level of tire wear and determine when it's time for a replacement.

- Tire Pressure Gauge. This tool allows you to check the tire pressure.

- Wheel Diameter Gauge. This tool can be used for accurate and precise wheel or rim diameter measurements.

Accurate measurements help identify potential issues such as low tread, uneven wear, and improper tire inflation, all of which can compromise the vehicle's and its occupants' safety. By spotting such issues early on, you can take corrective action to prevent premature tire wear and extend the life of your tires.

Some regions have legal requirements regarding tire specifications, such as minimum tread depth limits. Using properly calibrated equipment helps ensure compliance with these regulations.

Safety Precautions When Handling Tires

Protecting yourself should be your top priority when working with tires. Here are some essential safety measures to follow when dealing with tires:

- Wear Personal Protective Equipment (PPE): Always wear sturdy gloves and safety goggles to protect your hands and eyes from sharp objects, debris, and chemicals.

- Be Cautious of Weight: Larger tires can be heavy and dangerous to handle. Always be aware of the size and weight of the tire to prevent it from dropping or resulting in an accident.

- Avoid Heat and Flames: Tires are flammable and can be a safety hazard. Keep the tires away from open flames or any heat source.

- Proper Inflation: When inflating tires, use a pressure gauge and make sure the tires are inflated to the correct pressure. Overinflated or underinflated tires can be dangerous and negatively affect your vehicle’s performance.

Calculating Tire Size Using Online Tools

Nowadays, determining tire sizes and discovering the best options is even easier with the availability of virtual tools. You can use Caliber Auto Care’s virtual tire size by VIN tool to quickly access tire information and explore various choices to find the most suitable fit.

Measuring Tire Diameter

If you need to manually measure your tire’s diameter, start by laying it on a flat surface with no incline. Using a stiff tape measure, measure the tire from the top to the bottom. Make sure to measure over the hubcap, not from the side.

To obtain the most accurate results, measure multiple points along the tire's diameter.

Measuring Tire Width

To determine the tire width, measure from one edge of the tire to the opposite edge using a tape measure. If the tire is not mounted on the car, stand it upright during the measurement process.

Identifying the tread width is also essential for accurate measurements of tire width. The tread width represents the actual contact patch of the tire that comes into contact with the road surface, and it changes with vehicle weight and tire inflation.

Measuring a tire’s tread width is a straightforward. First, ensure that the tire it is cool to the touch and not heated from recent driving. Position a ruler or tape measure across the tread of the tire, running from one edge of the tire's tread to the other. Make sure the measuring tool is perpendicular to the tread and rests flat against it. Read the measurement at the widest point of the tread, where the tool intersects with the tire.

To ensure precision, consider taking multiple measurements at different locations around the tire and averaging them.

The section width is the distance across the widest part of the tire when it is mounted on a wheel and inflated to the recommended air pressure. It is measured from one sidewall to the other in a straight line.

Measuring Aspect Ratio and Sidewall Height

The tire aspect ratio is a critical parameter that describes the relationship between the tire's sidewall height and section width. It is represented as a percentage and is calculated using the following formula:

Aspect Ratio = (Tire Sidewall Height / Tire Section Width) x 100

Tires with a higher aspect ratio (e.g., 65 or 70) generally have taller sidewalls. These tall sidewalls act as a cushion, providing a smoother ride and more comfort.

Tires with a lower aspect ratio (e.g., 40 or 50) have shorter sidewalls, improving cornering stability and steering responsiveness.

Measuring Wheel Diameter

It is essential to know your wheel size to find the appropriate tire size. Identifying the proper rim size ensures the tires fit correctly on the wheels and function optimally.

You can measure the wheel diameter using a measuring tape. Identify the widest point of the wheel's diameter and stretch the measuring from one edge to the opposite edge, keeping it flat against the wheel's surface.

Measuring Tread Depth

Your tires must have sufficient tread depth as it provides the required grip, reduces braking distance, and enhances safety, especially in challenging weather conditions. Worn-out tires with shallow tread can reduce cornering grip and lead to a loss of control on the road.

Monitoring tread depth and keeping it within safe limits can help you extend your tire’s lifespan.

You can use a tire depth gauge to measure the tread depth. All you have to do is insert the probe of the tire depth gauge into the center of a tread groove until the base of the gauge rests on the tire.

If the depth is 5/32” or more, your tire is in excellent condition and will perform optimally. A 3/32”-4/32” tread depth indicates that your tire is getting worn down, and you may have to replace it soon.

At 2/32” or less, your tires need to be replaced immediately as braking distance and vehicle control are impacted at this point.

Measuring Tire Pressure

Keeping your tires inflated at the recommended pressure is critical to tire maintenance. Low-pressure tires can pose significant risks, such as low response to steering, handling, and braking — increasing the chances of a collision. Underinflated tires also have a higher rolling resistance which can reduce your fuel economy.

On the other hand, over-inflated tires are not a safety concern, but they aren’t ideal either. Continuing to drive with over-inflated tires can lead to more rapid tread wear and a more frequent need for replacements.

Using a tire pressure gauge is an easy way to check tire pressure and keep it at the correct levels.

- Locate the tire valve and remove the threaded cap.

- Press the tire pressure gauge against the valve and keep it in place, preventing air leakage. If you hear a hissing sound, adjust the angle of the gauge.

- To get the current pressure, simply observe the slide ruler on manual pen gauges, the dial on dial pressure gauges, or the digital screen on digital pressure gauges.

Note that the most accurate source for tire pressure information is your vehicle's owner's manual. It will typically provide the recommended tire pressure for both the front and rear tires. Look for the section on tire maintenance or specifications. Also, Many vehicles have a tire placard located inside the driver's side door jamb, on the door itself, or in the glove compartment. This placard displays important information, including the recommended tire pressure for your specific vehicle.

Additional Considerations for Special Tires

All-terrain and off-roading tires are measured differently, mainly due to the specialized nature of off-road tires and their intended usage in challenging terrains. While standard tires often use a metric sizing system (e.g., 225/55R18), off-road tires may use an alpha-numeric system (e.g., 33x12.50R15).

Common Tire Measurement Mistakes to Avoid

Several potential pitfalls and inaccuracies can arise when measuring tires, leading to incorrect readings.

Placing the tire on an uneven or sloped surface while measuring can lead to distorted readings. In addition, if the tire has uneven wear, measuring the tread depth at different points may yield inconsistent results.

Also, ensure you have a reliable and well-calibrated tire gauge for precise measurements. Always measure the tread depth at multiple points around the tire to get a comprehensive picture of tire wear.

Taking double measurements of tires is recommended to ensure accuracy and consistency in the readings.

Conclusion

Choosing tires compatible with your vehicle and inflating them to the recommended pressure can help improve gas mileage and reduce overall fuel consumption.

With consistent and accurate measurements, you can make improved decisions about tire replacement.

To ensure accurate tire measurements, it is essential to consult the vehicle owner's manual, the sidewall of the tire, or a qualified tire professional like the specialists at Caliber Auto Care. Remember to take the measurements based on the recommended procedure to achieve reliable results.